Look what our lab team have been up to

Wireless Equipment

October 8, 2022

pH Measurement

October 8, 2022

Extra Low Pressure Calibration

Low pressure calibration can present challenges not experienced with normal to high pressure work.

Conventional pressure pumps just don’t have the resolution or stability to work at very low pressures.

This was the situation we found ourselves in recently, when we were approached by a pharmaceutical company who needed to calibrate their pressurised rooms.

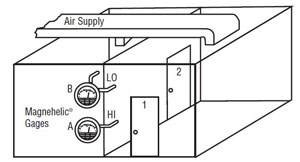

Positive Pressure Clean Rooms

Positive pressure cleanrooms are used in the electronics, medical and pharmaceutical industries to prevent the ingress of dust or other particles. Conversely in industries that produce nasty odours, negative pressure may be used to keep smells in.

Pressure Measurement

The most common instrument for measuring this differential pressure is the Magnehelic gauge. (These days, although the Magnehelic is still a huge seller for Homershams, there are many digital alternatives too).

As you might imagine, the amount of pressure differential is very small; typically in the region of 30 to 60 Pa, or 0.03 to 0.06 kPa.

Importance of Calibration

In pharmaceutical manufacturing, there is no room for error. Customer health depends upon perfectly executed production, such that every process must be checked and verified.

All processes ‘drift’ over time and calibration is the way to ensure that these changes are corrected and accounted for. Laboratory accreditation ensures that the lab performing calibrations performs to internationally accepted best practice and that their equipment, techniques and staff all conform.

The Homershams laboratory has been IANZ accredited for pressure since 1980.

Special Low Pressure Challenges

So while initially delighted that our pharmaceutical customer required accredited calibration, we rapidly became aware that while our labs capabilities were excellent up to 70 MPa, we could not handle the requirements of a calibration at almost 1 million times less than this with our current equipment. We therefore purchased new equipment allowing us to service this customer and others to come.

Customers Premises

The customer’s facility consists of a number of positive pressurised rooms monitored both by analogue gauges and a computerised SCADA system.

The customer needed to have the system calibrated and verified.

Calibration Procedure

The calibration procedure involves generating an accurate and stable pressure, applying this to the instrument under test and comparing the results (at multiple points and times) against a test instrument at least 4 times more accurate than the system under test.

“Trust but Verify”

“Trust but verify” was the famous quote by Ronald Reagan on Soviet disarmament. As mentioned above, IANZ are the body that verifies laboratory performance, and a lab is only as good as its performance.

Take a look at the calibration section of our website and feel free to contact us if we can help.